The automotive supply chain is very complex due to detailed manufacturing processes and wide distribution networks. But disruptions are seen as the biggest risk to business growth, even more so than problems like rising costs. Companies have to use new technologies and proven strategies to make more money in this tough business.

Digital Transformation

Outdated manual systems in automotive supply lines cannot collect accurate and extensive data for making good decisions. If companies have access to abundant and accurate data, they can make better plans and estimates for the future. Similarly, leaders can connect important data by switching to digital operating models. It helps makers and suppliers learn more about their markets and customer’s needs, so they can adopt the latest business trends.

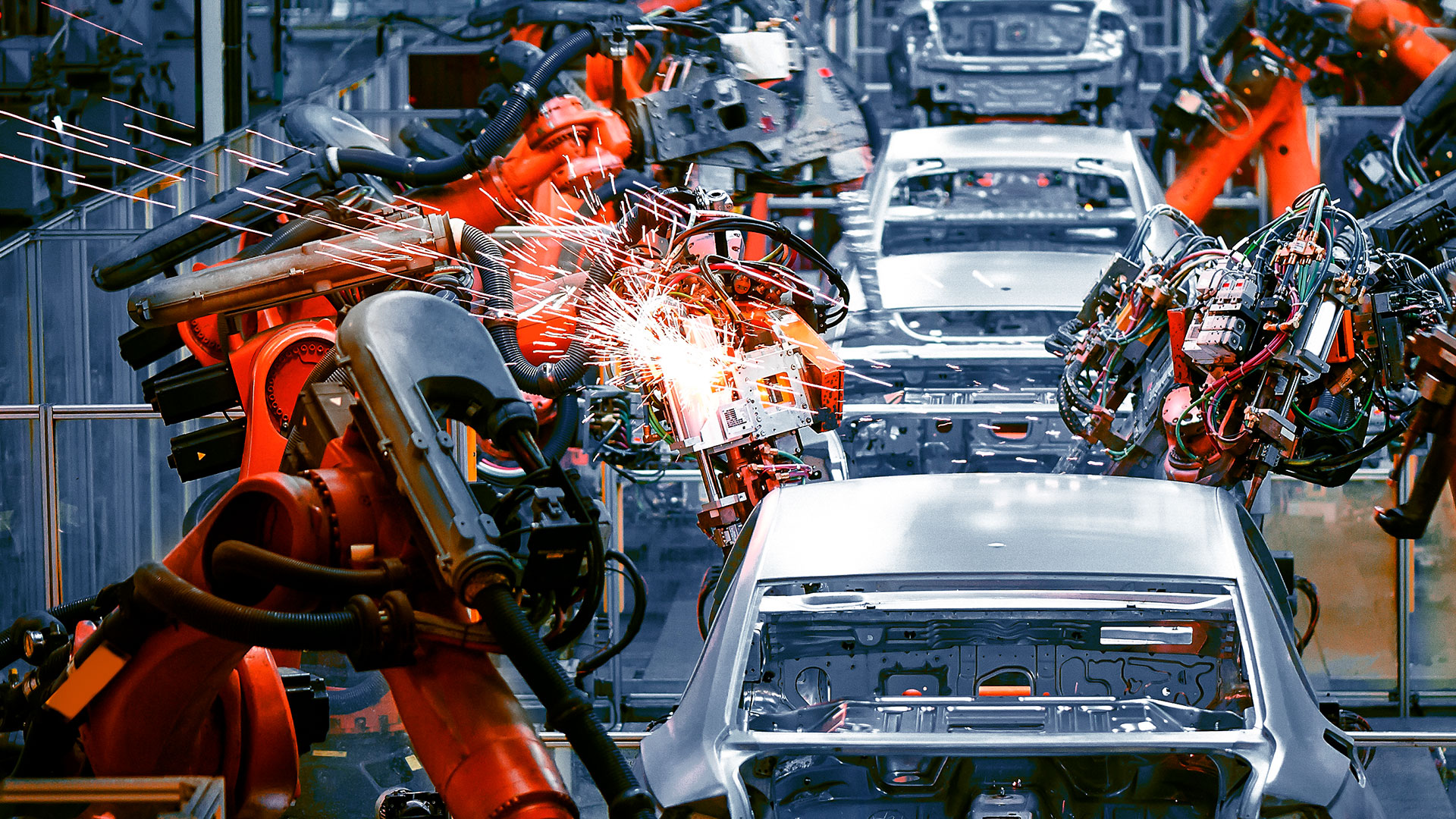

Robotics, GPS Tracking Systems & IoT Sensors

The automotive transport industry cannot survive without efficient GPS tracking systems and Internet of Things (IoT) monitors. They keep an eye on vehicle location, speed, and condition, which is essential for an efficient supply chain system. This technology improves awareness and lets logistics managers make quick decisions. Meanwhile, the addition of robotics is another game changer to the automotive supply chain because it automates tasks more efficiently than humans. As a result, this cuts down on labor costs and increases output by speeding up cycle times and throughput.

Local Parts Sourcing in Automotive Supply Chain

Effective supply chains highly depend on smart sourcing which means finding goods locally. Automobile companies can cut down on the costs and delays in shipping if they work with local suppliers. If manufacturers work with more and more local vendors, their company will be more quick and flexible, so it can better meet the changing needs of the market.

Optimization of Logistics

Companies can plan, track, optimize, and carry out deliveries all from one platform with the help of advanced logistics solutions. This makes logistics processes faster and more reliable for a broader supply chain. They can plan routes and make drivers more productive with the help of advanced transportation software. Centralized control of logistics operations is another advantage that makes coordination easier and allows quick responses. Logistic optimization can be an incredible resource that lowers transportation costs and raises customer satisfaction.

Multimodal Transport Options for Efficiency

Auto transport supply chains can be optimized in a variety of ways with the help of multimodal transport solutions. Companies can use the best features of each mode of transport according to the customers’ needs. They can strategically combine train, sea, and road modes of transport and go for the best option. For example, rail travel can be the go-to option for long distances due to its lower fuel consumption. At the same time, sea transport makes foreign shipping more cost-effective. Road transport is a common and very important last-mile service due to its flexibility and quick responses. By combining these modes in the best way possible, you can create a fair supply chain.

Boost Your Automotive Supply Chain!

Supply chains are changing more quickly, so transportation fleets need to have efficient car transport solutions to deal with future uncertainties. This gives companies a competitive edge over their competitors. Companies can adopt cutting-edge technology and flexible tactics to quickly adjust to changing supply chain dynamics. Make your supply system have a competitive advantage and meet market demands effectively.